Based on the current service condition of the steel-making converters, Huaxi Special Steel has decided to organize a company-wide shutdown and overhaul from April 17 to April 27, 2024. In light of the current equipment usage and process defects, all departments are required to organize internal and external units to conduct reasonable maintenance and repairs on all equipment within their jurisdictions, ensuring that all equipment performance reaches its optimal state after the overhaul and the equipment’s service life is extended.

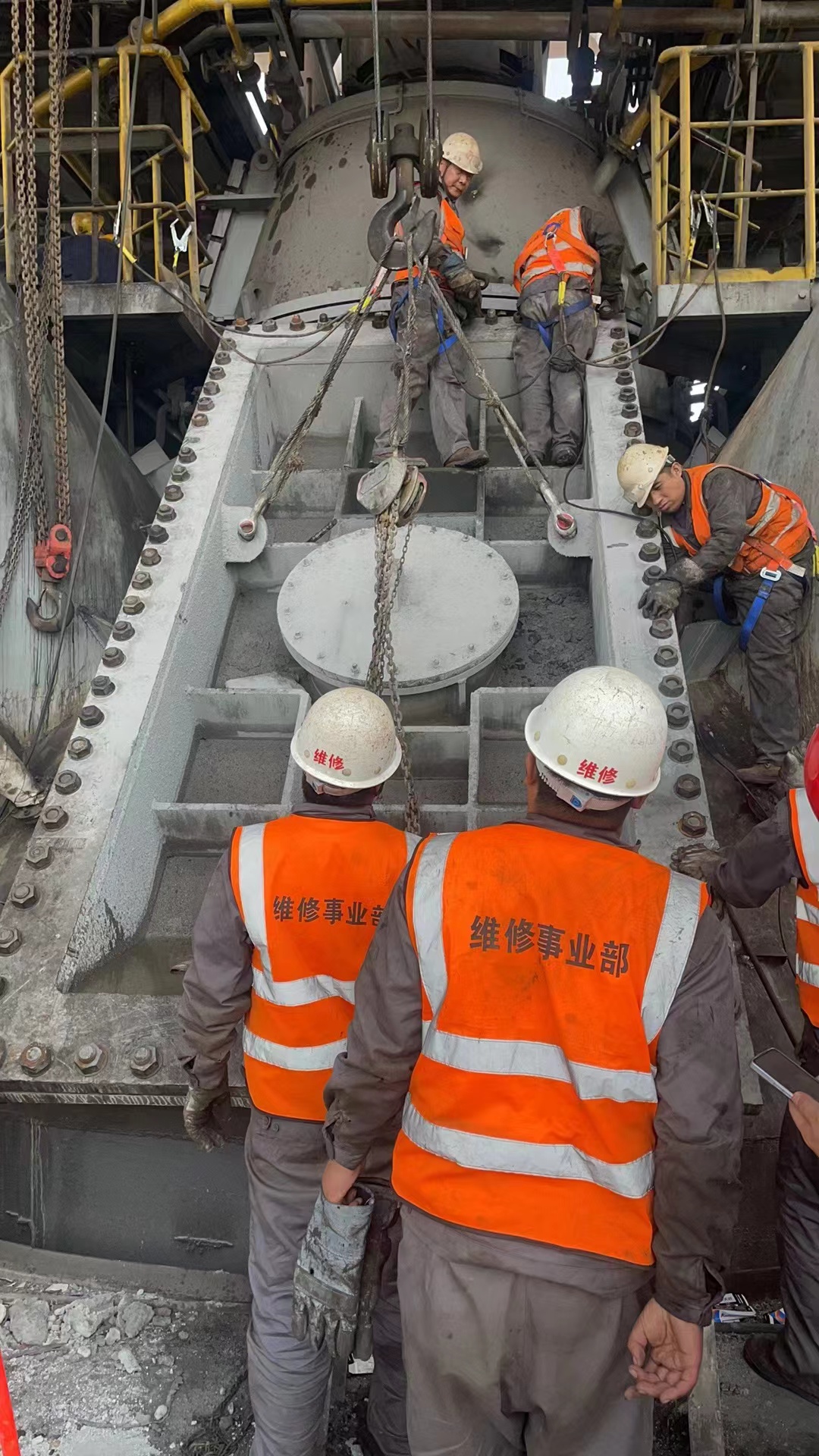

Given the tight schedule and heavy workload of this overhaul, which involves hot work operations, confined space operations, lifting operations, high-altitude operations and gas-related operations, the Company’s leadership attaches great importance to achieving proper management coordination and reasonable arrangements. A maintenance command has been established to determine the responsible persons at all levels and departments, and an overhaul plan has been formulated, including safety measures and emergency response measures, so as to ensure the safety of personnel and equipment during the overhaul as much as possible. Each plant has formulated a practical maintenance plan based on its own conditions, with the maintenance schedule time accurately calculated to the hour, and the maintenance tasks assigned to individuals to ensure that the maintenance can be completed on time and according to the schedule. All maintenance personnel have carried forward the professional dedication of not being afraid of hardship, not being afraid of tiredness, and being loyal and dedicated. They strive to advance the maintenance progress so as to complete the maintenance plan on time and as scheduled.

During this overhaul, the metalworking workshop of the equipment department undertook the installation and welding of DN1800 valves, and welders Pang Chuanshuang, Li Liang and Li Qi were responsible for welding the pipelines. The pipeline needs to be welded on both sides to bear the pressure. It enters through a one-meter square manhole. The internal space is small and it is a confined space operation. Additionally, there is a presence of a small amount of gas within the space. Prolonged welding in the pipeline can also lead to oxygen deficiency, necessitating that the workers wear breathing apparatus. They must also endure temperatures within the pipe that can reach fifty to sixty degrees Celsius. Pang Chuanshuang, Li Liang and Li Qi displayed the spirit of loyalty, dedication, hard work and endurance, and completed the welding tasks on time with guaranteed quality and quantity under relatively harsh conditions. The entire operation was carried out in accordance with the Confined Space Work Permit system, and was successfully completed under the supervision of three personnel from the Coal Safety Station.

During this major overhaul, the Group Headquarters dispatched over 70 maintenance workers to provide support, which undoubtedly offers strong technical support and human resource assurance for Huaxi Special Steel’s overhaul work. These maintenance workers are all professionally trained and possess rich practical experience. Their arrival will inject new vitality and momentum into Huaxi Special Steel’s overhaul work, which ensures its successful completion. During the maintenance process, issues such as severe aging of some equipment and difficulties in dismantling were encountered. In response to these problems, the maintenance workers from Headquarters, drawing on their extensive experience, quickly formulated solutions. They employed advanced maintenance techniques combined with traditional methods, successfully resolving these challenges and ensuring the smooth progress of the maintenance work. Cao Yingjie is one of these workers, who was responsible for welding the dust removal pipes during this maintenance period. Welding the exterior of dust collection pipes is considered high-altitude work. In addition to enduring the physical discomforts of working at height, the worker must either crouch, climb, or straddle in the welding position for half a day, sweating profusely despite the mild spring weather.

This maintenance inspection is a critical juncture for conducting a comprehensive and thorough examination and maintenance of the equipment. Its aim is to ensure that the equipment operates more stably and reliably going forward, thereby better supporting the overall operations and the implementation of the development strategy. Although it is just a pause in the Company’s development journey, it is of great significance. Only through careful maintenance and repair during this period can we effectively prevent potential failures, extend equipment life and improve production efficiency. This overhaul, aiming for better progress, is just a short break on the Company’s long journey. In the days to come, we will continue to carry forward our professionalism, continuously expand our business areas, constantly improve our core competitiveness, and inject new impetus into the development of the Group.

Hua Xi

Special Steel

✦

learn more

✦

WeChat Scan

Follow Us

Sales Hotline|15230468683

冀公网安备13020002000120号

冀公网安备13020002000120号