Huaxi Special Plates Company is part of the Phase II construction project of Huaxi Special Steel. With a total investment of 5.47 billion yuan, the project began its design phase in October 2023 and is planned to be completed and put into operation by the end of December 2024.

The construction of the project has further expanded the profit margins of steel products. It also marks the end of the era when the Huaxi base only produced steel billets without rolled steel products. The project adheres to the principles of high-quality development and enhancing new productive capacities. Guided by the concepts of efficiency, energy conservation, low carbon emissions, and green development, the project features well-equipped facilities, automation, intelligence, and a high starting point, ranking it among the top wide plate production lines in the country.

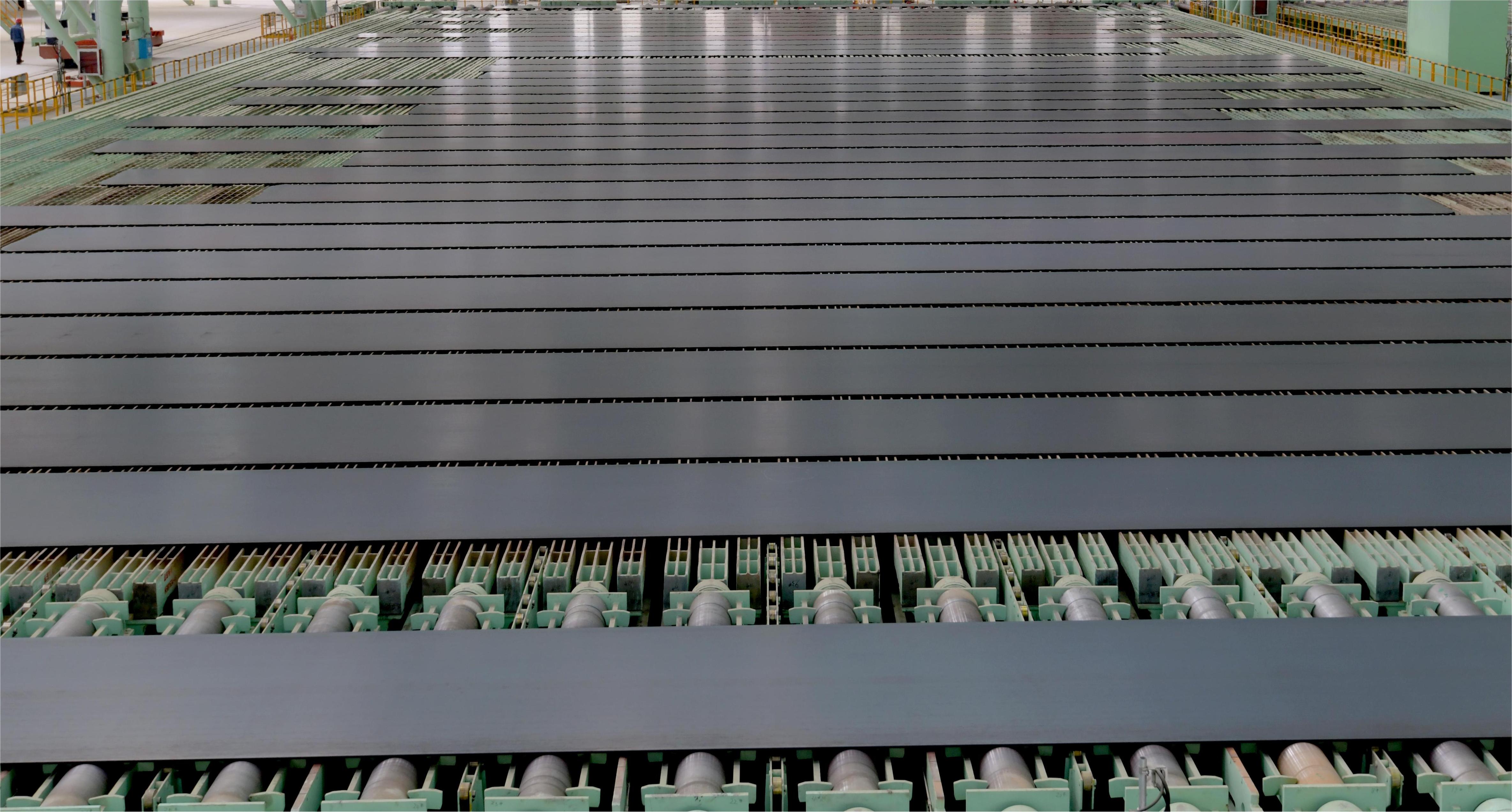

The project is designed for an annual production capacity of 2 million tons of wide and thick plates. The main equipment includes one LF refining furnace, one double-stream slab continuous casting machine, three walking beam reheating furnaces, a high-pressure water descaling machine, a roughing mill, a finishing mill, a hot leveling machine, a hot cutting shear, an online ultrasonic flaw detector, a head-cutting shear, a double-sided shear, and a length-fixing shear, among others. The products cover a full spectrum of varieties, primarily including low-alloy high-strength structural steel, high-quality carbon structural steel, high-rise building structural steel, bridge structural steel, shipbuilding and offshore engineering steel, boiler and pressure vessel steel, wear-resistant steel, weathering steel, and others. The product specifications range in thickness from 6 to 200 mm and in width from 1,600 to 3,600 mm, with mechanical properties guaranteed for thicknesses up to 150 mm.

The project construction adheres to the principle of the “Four First-Class Standards”, fully leveraging the resources of the Headquarters for construction, replicating and optimizing the Headquarters’ design plan, comprehensively shortening the construction period, ensuring quality, controlling investment, and implementing refined management. To ensure the timeline, the project’s infrastructure construction is divided into four sections, with equipment installation planned for July. Continuous operation of construction machinery and 24-hour work shifts will be maintained to ensure that the project is put into production by the end of 2024. The aim is to achieve both investment and output within the same year, so as to deliver a satisfactory result to the Group Company.

Hua Xi

Special Steel

✦

learn more

✦

WeChat Scan

Follow Us

Sales Hotline|15230468683

冀公网安备13020002000120号

冀公网安备13020002000120号